Intro to 3D Laser Scanning: What It Is and Why It Issues

What Is 3d Laser Scanning Technology .3D laser scanning is a transformative modern technology that has reinvented the way we capture and analyse the real world. From industrial layout to heritage preservation, this innovation offers a specific and reliable way to produce detailed digital models of items, structures, and landscapes. In an increasingly digital age, understanding the basics of 3D laser scanning is essential for markets and specialists looking for to stay in advance of the contour. This short article offers an extensive introduction to 3D laser scanning, discovering what it is, why it matters, and the numerous means it is being used across different fields.

What Is 3D Laser Scanning?

At its core, 3D laser scanning is a modern technology that records the form of physical items using laser light. It functions by emitting laser beams that jump off surfaces and return to the scanner, which after that calculates the range based upon the moment it takes for the light to return. This procedure, referred to as time-of-flight measurement, allows the scanner to generate precise three-dimensional representations of the checked things or environment.

These depictions are often referred to as factor clouds, which are dense collections of information factors in a three-dimensional coordinate system. Each point in the cloud represents an accurate area on the surface of the checked item, capturing not just its form yet likewise its texture and colour (depending upon the type of scanner utilized). As soon as caught, these factor clouds can be refined and converted into 3D designs using specialist software program.

The Elements of a 3D Laser Scanner

A normal 3D laser scanner contains several essential elements:

-

Laser Emitter: This element produces the laser beam that is predicted onto the things or surface area being checked.

-

Receiver/Detector: The receiver identifies the laser light as it shows back from the item. It measures the time taken for the light to return, which is then made use of to calculate the distance between the scanner and the things.

-

Revolving Mirror: In several scanners, a turning mirror is utilized to guide the laser beam of light throughout the things. This permits the scanner to capture data from various angles, ensuring that the whole surface of the things is covered.

-

Control System: The control system manages the operation of the scanner, consisting of the timing of the laser pulses and the activity of the turning mirror.

-

Data Processing Software Application: Once the raw information is collected, it requires to be processed right into a usable style. Specialized software program is made use of to convert the point cloud information right into a 3D version, which can after that be analysed, modified, or integrated into various other digital systems.

Kinds Of 3D Laser Scanners

There are several kinds of 3D laser scanners, each fit to different applications:

-

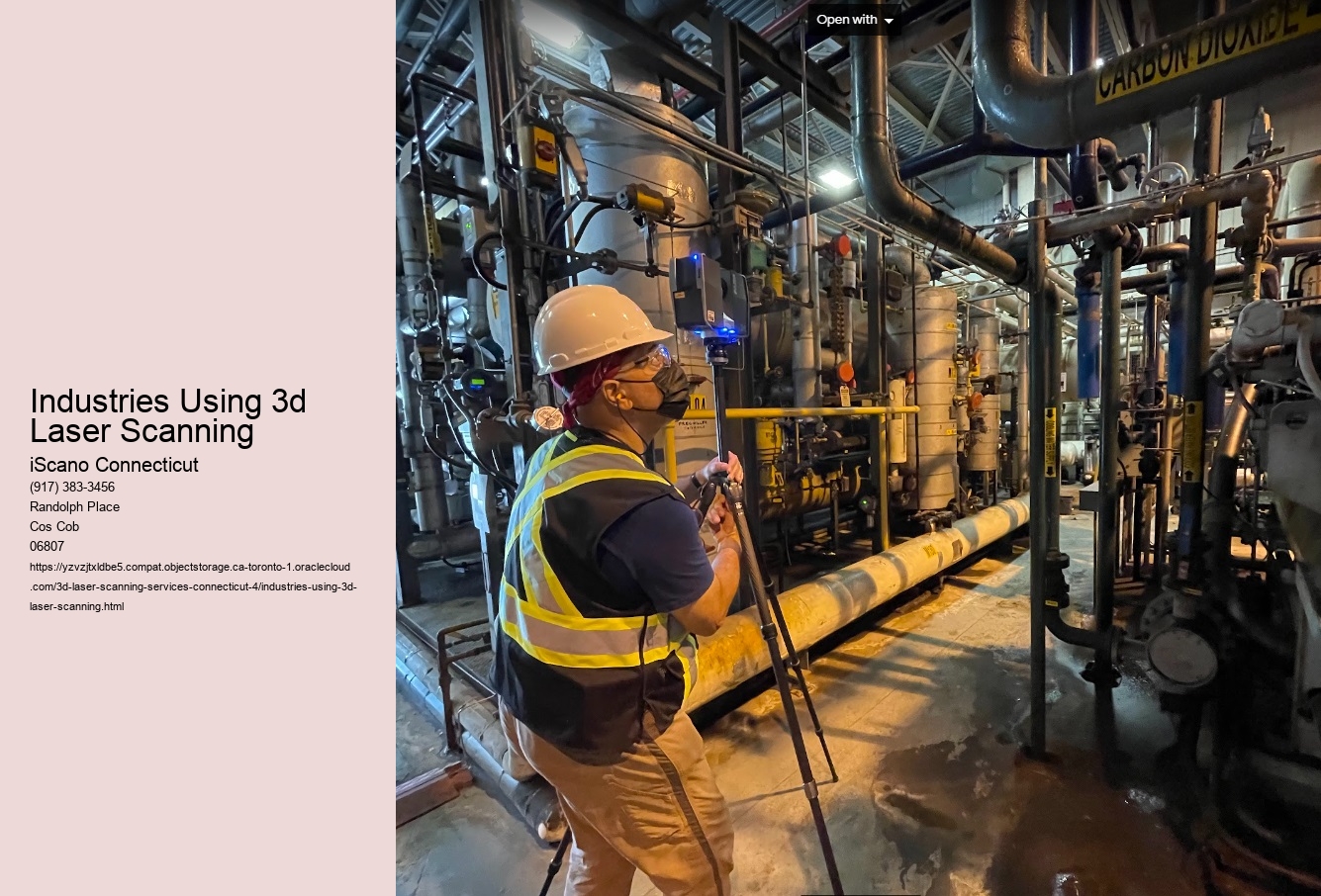

Terrestrial Laser Scanners (TLS): These scanners are normally used for massive jobs such as checking buildings, bridges, or landscapes. They are placed on a tripod and can capture information from long distances, making them perfect for outside usage.

-

Handheld Laser Scanners: As the name recommends, these scanners are mobile and can be utilized to capture smaller objects or areas that are hard to reach with a larger scanner. They are frequently utilized in sectors such as automobile, aerospace, and manufacturing.

-

Aerial Laser Scanners (LiDAR): LiDAR (Light Detection and Ranging) is a sort of laser scanning that is commonly installed on aircraft or drones. It is used to record large topographical data, such as woodlands, mountains, or city locations.

-

Structured Light Scanners: Unlike conventional laser scanners that utilize a solitary laser beam of light, structured light scanners forecast a pattern of light onto the things. By evaluating the contortion of the pattern, the scanner can produce a 3D version. These scanners are frequently made use of for in-depth inspections in production and quality control.

Why 3D Laser Scanning Issues

The significance of 3D laser scanning hinges on its capacity to give very accurate and comprehensive depictions of the real world. This ability has significant ramifications across different industries and applications:

-

Precision and Precision: 3D laser scanning can record countless data factors per second, causing extremely described and accurate models. This level of accuracy is vital in industries such as engineering, architecture, and construction, where also minor mistakes can have substantial effects.

-

Efficiency: Typical approaches of dimension and documentation can be taxing and labour-intensive. 3D laser scanning streamlines the process by catching extensive data in a portion of the time. This performance is specifically useful in large jobs, such as evaluating a building and construction site or recording a historical landmark.

-

Non-Invasive Data Collection: 3D laser scanning is a non-contact method, indicating that it does not need physical communication with the things being scanned. This is specifically vital when handling delicate or inaccessible objects, such as cultural heritage sites, archaeological artefacts, or harmful settings.

-

Adaptability: 3D laser scanning is a functional modern technology that can be applied in a large range of sectors, from production and building to medical care and enjoyment. Its capacity to capture complicated geometries makes it indispensable in any type of area that requires thorough spatial analysis.

-

Improved Visualisation and Evaluation: The 3D models created by laser scanning can be made use of for visualisation, simulation, and evaluation. For instance, architects can make use of these versions to produce online walkthroughs of buildings, while designers can mimic exactly how a structure will certainly act under different problems.

Overview of 3D Laser Scanning Technology

To comprehend the full effect of 3D laser scanning, it's vital to discover the modern technology behind it and how it has actually developed over the years.

The Evolution of 3D Laser Scanning

3D laser scanning has its origins in the very early 1960s, when the very first laser was developed. Initially, lasers were made use of mostly for clinical research study and armed forces applications. Nevertheless, as modern technology progressed, the capacity for utilizing lasers to measure ranges and capture detailed spatial data became apparent.

In the 1980s, the very first business laser scanners were presented, noting a considerable landmark in the growth of 3D scanning technology. These very early scanners were huge, pricey, and limited in their capabilities, but they prepared for future innovations.

The 1990s saw substantial renovations in laser scanning technology, with the introduction of even more compact and budget-friendly scanners. This duration likewise saw the growth of software program that could process point cloud information into 3D models, making the technology a lot more obtainable to a wider range of markets.

Today, 3D laser scanning is a fully grown technology that continues to progress. Developments in computing power, data storage, and software program formulas have made it feasible to catch and refine larger and much more intricate datasets. At the same time, the development of new scanning innovations, such as handheld and drone-mounted scanners, has expanded the variety of applications for 3D laser scanning.

Key Technologies in 3D Laser Scanning

Numerous crucial modern technologies are indispensable to the procedure of 3D laser scanners:

-

Time-of-Flight (ToF) Dimension: This is the most common approach utilized in 3D laser scanning. It involves determining the moment it takes for a laser beam to take a trip to a things and back to the scanner. By calculating the time-of-flight, the scanner can identify the distance to the things and produce a 3D factor.

-

Phase Change Dimension: In phase change dimension, the scanner gives off a continual laser beam that is modulated in amplitude. The stage difference in between the released and received light is made use of to compute the distance. This technique is commonly utilized in high-precision scanners and can accomplish greater precision than time-of-flight measurement.

-

Triangulation: Triangulation-based scanners utilize a laser beam and a camera to catch information. The laser forecasts a factor or line onto the item, and the camera records the reflected light. By evaluating the angle between the laser, the item, and the cam, the scanner can identify the range and generate a 3D point.

-

Structured Light: Organized light scanners forecast a pattern of light (such as red stripes or dots) onto the item. The deformation of the pattern is caught by an electronic camera, and the information is used to calculate the 3D shape of the item. Structured light scanners are understood for their high accuracy and are typically utilized in applications requiring thorough surface area measurements.

-

Multi-Sensor Assimilation: Some innovative 3D laser scanners incorporate several sensors, such as cams, GPS, and inertial measurement systems (IMUs), to enhance the accuracy and adaptability of the information. For example, LiDAR systems made use of in autonomous vehicles often integrate laser scanning with various other sensors to produce an extensive map of the setting.

Applications of 3D Laser Scanning

The applications of 3D laser scanning are huge and varied, with the modern technology being used in numerous markets:

-

Architecture and Building: 3D laser scanning is commonly made use of in the architecture and building industries to produce accurate as-built designs of buildings and infrastructure. These designs can be used for design, renovation, and maintenance functions, along with for clash detection in intricate tasks.

-

Production: In production, 3D laser scanning is made use of for quality control, reverse engineering, and prototyping. The capability to capture specific dimensions of parts and assemblies makes sure that items meet layout specs and feature as meant.

-

Social Heritage and Archaeology: 3D laser scanning plays an important function in preserving cultural heritage sites and artefacts. By developing comprehensive digital documents, scientists can examine and evaluate these treasures without taking the chance of damages. In addition, 3D models can be used for online restoration and visualisation, allowing the public to experience archaeological sites in new methods.

-

Medical care: In medical care, 3D laser scanning is used for a series of applications, including producing personalized prosthetics, orthotics, and dental devices. The innovation is likewise used in medical imaging and surgery planning, where accurate 3D designs of people' ' makeup are important for effective results.

-

Home entertainment and Media: The show business has accepted 3D laser scanning for creating sensible visual effects, computer animations, and virtual reality experiences. The modern technology permits filmmakers and game designers to record real-world settings and personalities, bringing a brand-new degree of realism to their work.

-

Transport and Framework: 3D laser scanning is utilized in transportation and infrastructure jobs to evaluate roads, bridges, passages, and railways. The data collected can be used for planning, style, and maintenance, making sure that these essential frameworks stay secure and functional.

-

Environmental Monitoring: LiDAR, a kind of 3D laser scanning, is widely used in environmental monitoring and natural resource monitoring. It is utilized to map forests, procedure plant life growth, display coastal erosion, and analyze the effect of natural calamities.

The Future of 3D Laser Scanning

As innovation continues to advance, the future of 3D laser scanning looks appealing. Several of the crucial fads and growths that are most likely to form the future of this technology include:

-

Increased Automation: The assimilation of artificial intelligence (AI) and machine learning right into 3D laser scanning systems will certainly make it possible for greater automation in data collection and handling. This will reduce the demand for manual intervention and enhance the speed and performance of scanning operations.

-

Miniaturisation and Mobility: As scanners diminish and much more mobile, they will be easier to release in a broader series of settings. This will open up brand-new possibilities for applications in areas such as space exploration, calamity reaction, and wearable innovation.

-

Real-Time Processing: Advances in computing power and information storage space will enable real-time processing of point cloud data, allowing customers to view and evaluate 3D versions on the area. This will certainly be especially important in sectors such as construction and surveying, where prompt feedback is vital.

-

Integration with Various Other Technologies: The future of 3D laser scanning will likely entail greater assimilation with other modern technologies, such as drones, robotics, and the Internet of Things (IoT). This will certainly make it possible for a lot more comprehensive data collection and evaluation, bring about new understandings and applications.

-

Democratisation of 3D Scanning: As 3D laser scanning technology comes to be much more economical and accessible, it will be taken on by a broader series of industries and specialists. This democratisation will certainly drive technology and increase the use cases for 3D scanning, making it a crucial device in the electronic age.

Final thought

3D laser scanning is an effective and functional technology that has changed the method we catch and evaluate the real world. Its capability to offer accurate, detailed, and effective dimensions has made it an indispensable device across a wide range of markets, from building and making to healthcare and cultural heritage. As the innovation continues to develop, we can expect to see also greater advancements in automation, transportability, and integration, paving the way for brand-new applications and opportunities. Whether you're an engineer, engineer, archaeologist, or filmmaker, recognizing 3D laser scanning is vital for remaining ahead in a significantly electronic world.